Electric motor housing

AionaCast has set off to revolutionise the manufacturing process for electric motor housings cast from Aluminium with a patented pending innovation intended for the application in electric passenger cars and heavy-duty vehicles.

The company has developed an innovative housing for electric traction motors which increases the cooling performance, reduces the weight and eliminates the risk of leakage. In addition, it comes with a substantial reduction in costs.

Generation 1

Generation 2

Generation 1

Generation 2

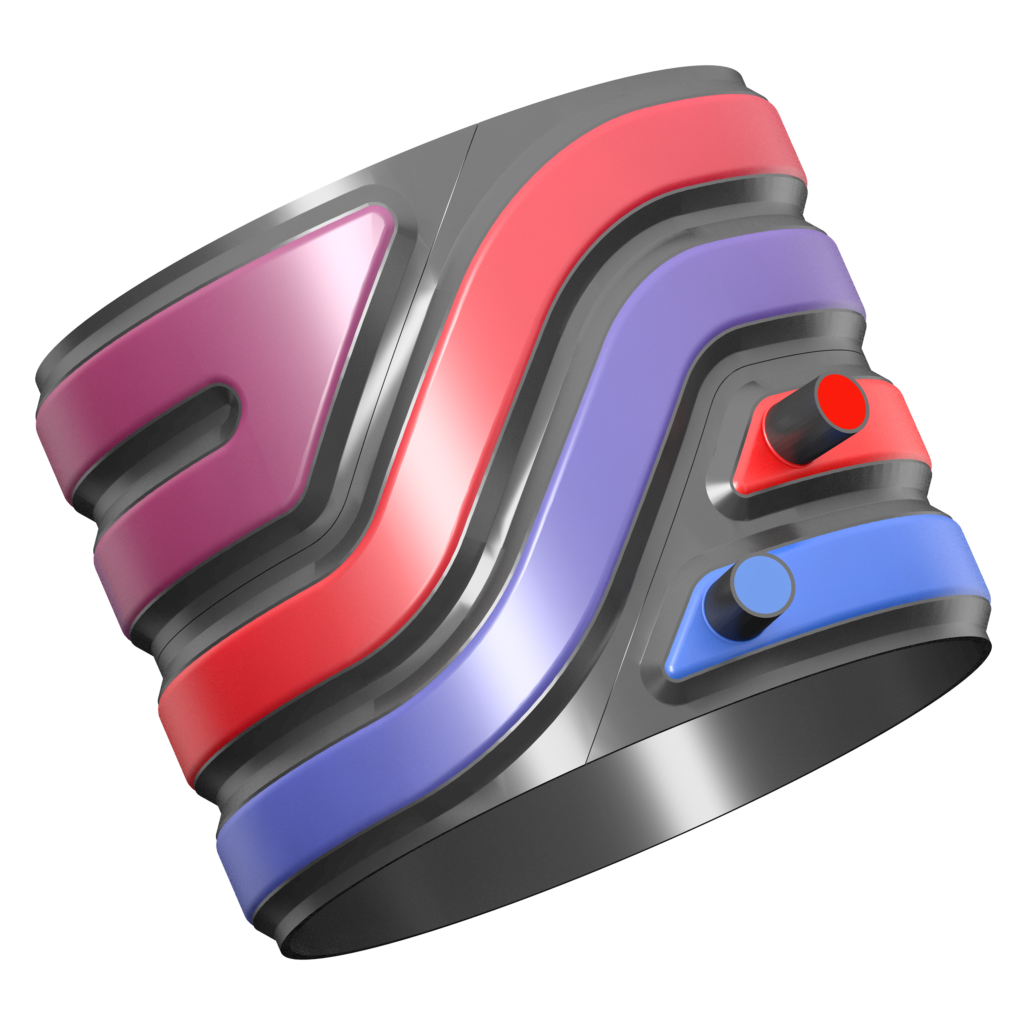

RoBoC Design Generation 2

By proof-of-concept AionaCast has shown feasibility. Here, only little attention was paid to the cross sections for the coolant or to the weight reduction.

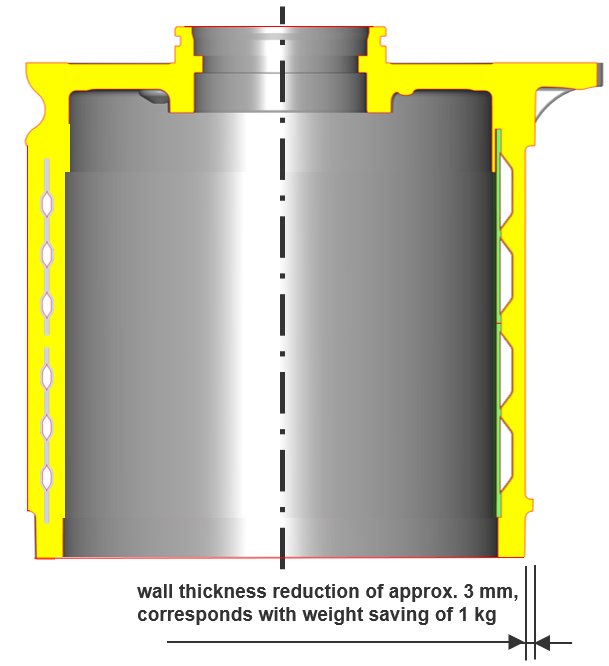

Now, the team realised the second generation in which the inserted and inflated plate has direct contact with the stator increasing the efficiency even more and reducing the weight.

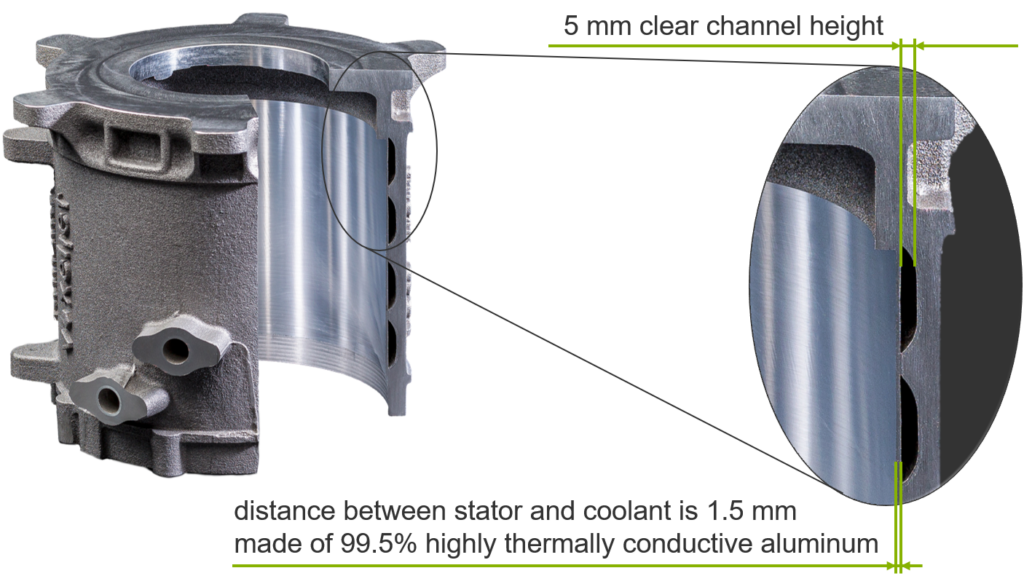

Using this approach, the wall thickness between stator and water-cooling channels can be reduced from approximately 5 mm to 1.5 mm. The reduced wall thickness is directly reflected in a reduced total weight of the housing for a typical BEV traction motor of about 1 kg.

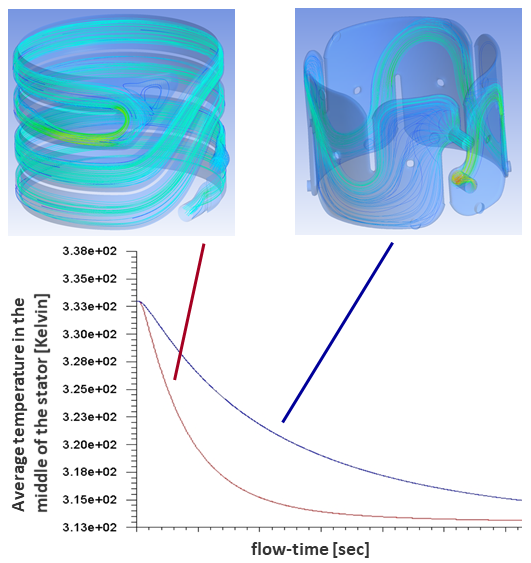

Moreover, as a consequence of all of the optimisations the reaction time is significantly shorter as well. To verify the system’s performance a conventional traction motor of a major manufacturer was compared to the RoBoC Gen2 using CFD (Computational Fluid Dynamics) flow simulations. Cooling the temperature in the stator from 60°C to 40°C can now be achieved in 30% of the time.

A welcomed side-effect is the significantly faster casting process. The time until the component can be removed from the casting tool is fundamentally shorter due to the direct cooling of the Aluminium cast from the inside.

- The helix design and the smaller distance between stator and coolant results in a higher thermal efficiency

- The sealing of the cooling channel is independent from the casting quality. The concept allows gaskets to be omitted completely and due to the non-existent core sand residual particles are no longer a problem

- Various cost advantages promise great competitiveness: No assembly like in a two-shell design, no need for processing or closing of sand marks due to the absence of a sand core, no obligation for numerous quality checks and a significantly shorter casting cycle.

- Kupral S.p.A. (Italy): casting technology

- voxeljet AG (Germany): 3D printed forms for the core package

- LPM S.p.A. (Italy): casting equipment

- Peter Prinzing GmbH (Germany): Roll-Bond bending

RoBoC Design Generation 1

The newly developed process is the perfect combination of two established production methods.

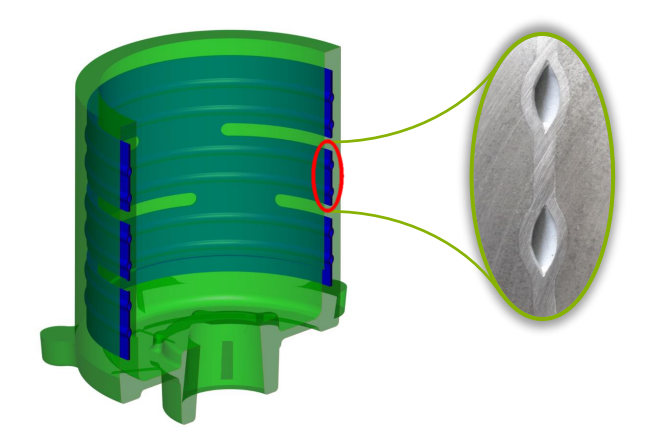

Here, a roll-bond core (short: RoBoC) is being inflated on one or both sides with approximately 100 bar compressed air and by that creating cooling channels in the customary dimensions.

This core is then placed in e.g. low pressure or gravity die casting tool and cast with Aluminium melt. During the casting process the core is tempered through the already existing channels, and thus preventing deformation or fusing.

The result is a metal plate integrated in the housing with the required structures needed for the cooling of the e-motor.

The layout of the cooling channels can be designed in a helix shape so that the hottest channel part is between the coolest and the second coolest area. This ensures a homogenous distribution of temperature without any hot spots during motor operation.

Such a design cannot be achieved using the classic two-shell design (e.g. out of high pressure die-castings), since a thermal short-circuit might be caused by overflowing from one channel to another. The RoBoC method allows tailor-made channel layouts including meandering or flat designs.

The sealing against coolant leakage, important for motor application, is provided by the self-contained roll-bond core and therefore independent from casting quality. So, the expensive helium leakage test for the water circuit on the final product, with a potential high loss of value added, becomes redundant.

In addition an assembly, required in two-shell designs, is completely unnecessary.

Operating in Germany, accessible locally, connected worldwide

Contact us

Located near Stuttgart, we’re based in the heart of an Automotive-focused region. Here, we benefit from an all-around view of the sector’s current activities.

info@aionacast.com

+49 (7042) 1200072

Roemerstrasse 17

71665 Vaihingen an der Enz

Germany